The Applications and Features of Portable Hardness Testers

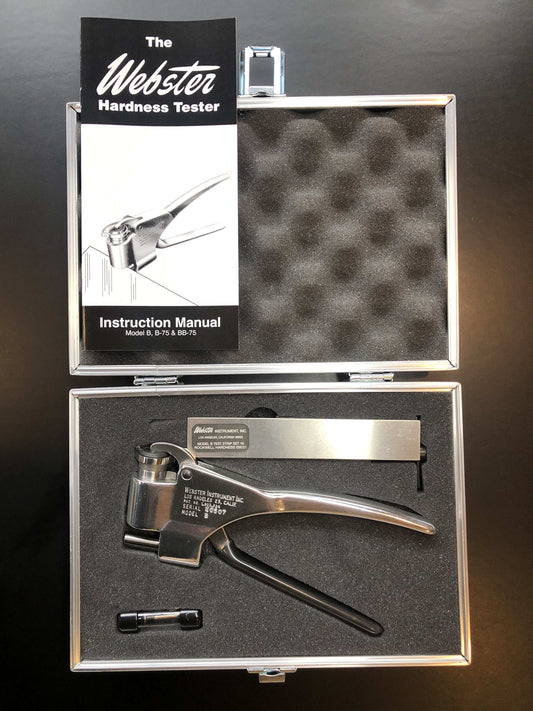

The WEBSTER® Hardness Tester is a fast and accurate gauge. Webster Instrument, Inc. makes it in 3 distinct models for testing aluminum, brass, copper, and mild steel. These hardness testers quickly identify tempers and assess a variety of shapes that other testers can’t, such as extrusions, tubing, and flat stock.

Each of our hardness tester models operates the same way and differs only in penetrator design, load spring type, and hardness ranges. Operation is simple. The work being tested is placed between the anvil and the penetrator. Pressure is then applied to the handles until the “bottom” is felt, then the dial indicator is read. Contact us to learn more about our hardness tester model.

Applications for WEBSTER® Hardness Testers:

- Can Be Used on Assemblies That Cannot Be Brought to the Labs

- Checks for Proper Heat-Treatment Response

- Differentiates Between Soft or Work-Hardened Material

- Gives a Rapid 100% Check on Parts That Would Normally Take a Long Time to Test

- Identifies Heat-Treated Parts

- Identifies Parts Made from Improper or Substandard Alloys

- Provides Correlation Between a Bench-Mounted Hardness Tester and the Production Line

- Segregates Materials in Stock

- Useful in Conjunction with Stationary Laboratory Hardness Testing Tools

Features of Our Hardness Testing Devices:

- Can Be Operated with One Hand

- Easy-to-Read Dial Indicator with 20 Graduations Permits Use as a “Go” and “No-Go” Gauge

- Round 3/8-Inch Diameter Anvil Can Test a Variety of Shapes

- Simple Operation Permits Readings Independent of the Operator’s Skill

- Tests Materials Up to 1/4 Inch in Thickness with Increased Capacities Available Up to 1 Inch

- Test Only Requires Applying Pressure to the Handles Until the “Bottom” Is Felt

WEBSTER® Products

-

WEBSTER® Hardness Tester

Vendor:Webster InstrumentRegular price $1,989.00 USDRegular price -

WEBSTER® Penetrator

Vendor:Webster InstrumentRegular price $143.90 USDRegular price -

WEBSTER® Standard Test Strips

Vendor:Webster InstrumentRegular price $16.75 USDRegular price -

WEBSTER® Verified Test Strips

Vendor:Webster InstrumentRegular price $108.75 USDRegular price